For measuring the flow rate of liquids and gases, turbine flow meters are frequently employed in a variety of sectors. At Saitechflow Instruments & Control, we offer a wide range of turbine flow meters that are designed to meet the unique needs of different applications. Here are some of the uses and benefits of turbine flow meters:

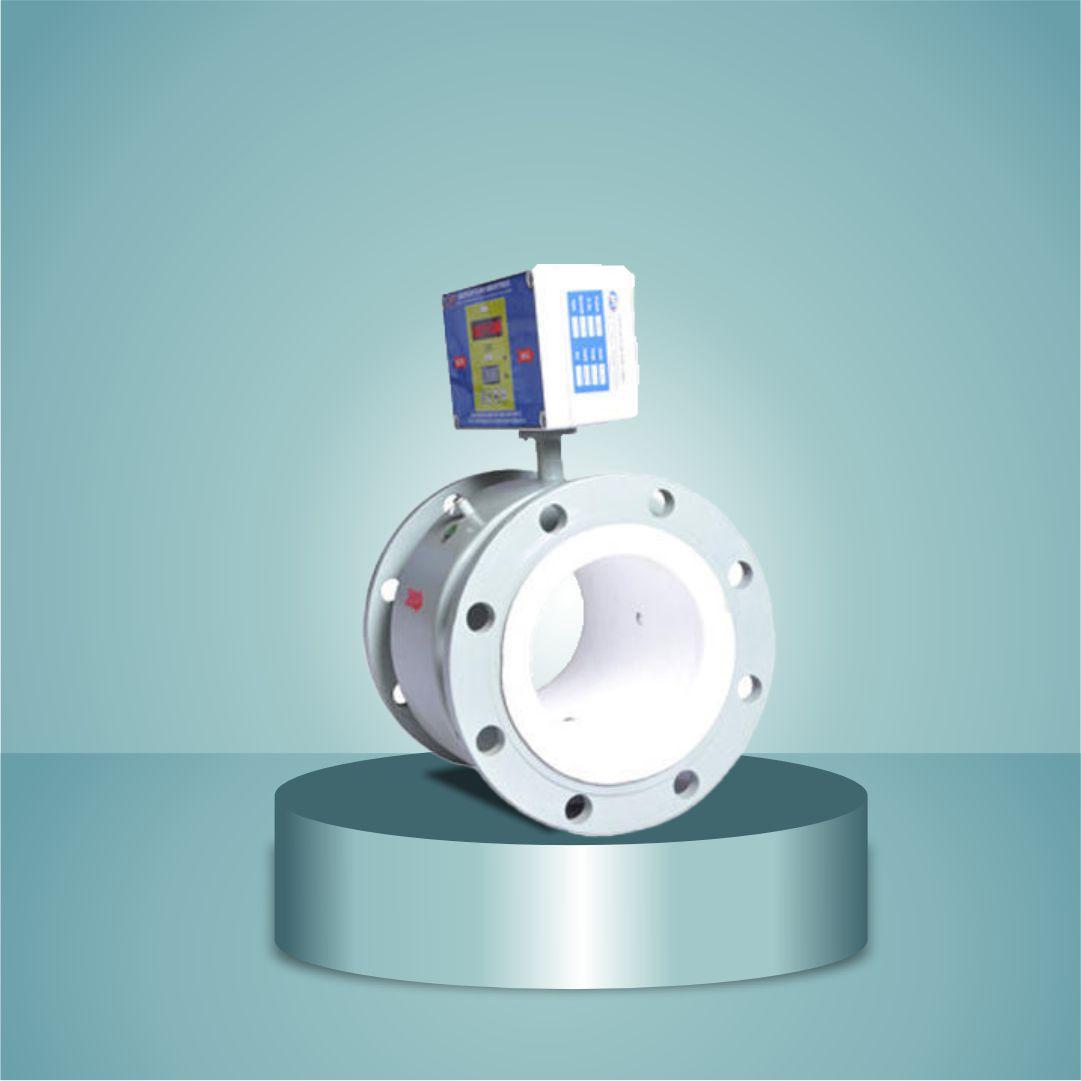

● Unobstructed Flow Path: Full bore flow meters offer a straight-through design, allowing the entire flow stream to pass through without any obstructions or restrictions. This design minimizes pressure drop and ensures accurate measurement of flow rates.

● High Accuracy: Full bore flow meters are known for their high accuracy in measuring flow rates across a wide range of flow velocities. This accuracy is essential for various industrial processes and applications.

● Wide Range of Fluid Compatibility: Depending on the materials of construction, full bore flow meters can be compatible with a wide range of fluids, including liquids, gases, and steam. They can handle corrosive, abrasive, and viscous fluids as well.

● Low Maintenance: Many full bore flow meters are designed for minimal maintenance requirements, resulting in reduced downtime and increased operational efficiency.

● Various Measurement Principles: Full bore flow meters utilize different measurement principles such as electromagnetic, ultrasonic, vortex shedding, or differential pressure. This variety allows for flexibility in selecting the most suitable meter for specific applications.

● Digital Display and Output: Some full bore flow meters come with built-in digital displays that show real-time flow rates and totalized flow. They may also offer digital communication protocols such as Modbus, HART, or PROFIBUS for integration with control systems.

● Multiple Size Options: Full bore flow meters are available in various sizes to accommodate different pipe diameters and flow rates. This ensures compatibility with a wide range of piping systems and applications.

● High Pressure and Temperature Ratings: Many full bore flow meters are designed to withstand high-pressure and high-temperature environments, making them suitable for demanding industrial applications.

● Environmental Protection: Some full bore flow meters are designed to meet specific environmental standards and certifications, ensuring reliable performance in harsh operating conditions.

● Self-Diagnostics and Alarms: Advanced full bore flow meters may include self-diagnostic features to detect any abnormalities or malfunctions in the meter. They may also have alarm functions to alert operators in case of irregularities.